Stadium LED Display Impact Resistance Testing

- Detail

Ensuring Safety and Durability: The Critical Role of Impact Testing for Stadium LED Displays

In high-energy sports environments where athlete safety and equipment reliability are paramount, stadium LED displays must undergo rigorous impact resistance testing. These comprehensive tests verify that displays can withstand accidental impacts while maintaining structural integrity and protecting both players and spectators.

Why Impact Resistance Matters in Sports Venues

Athlete Safety Priority

Player Collision Protection: Minimizes injury risk during game action

Equipment Durability: Ensures continuous operation through physical contact

Structural Stability: Maintains display positioning during accidental impacts

Public Safety: Protects spectators from potential falling debris

Industry Compliance Requirements

FIFA/UEFA Standards: Specific requirements for perimeter advertising

NBA/NFL Guidelines: League-specific safety protocols

International Building Codes: Structural safety compliance

Insurance Requirements: Risk mitigation for venue operators

Comprehensive Impact Testing Protocols

1. Mechanical Impact Testing

Test Method: Controlled pendulum or projectile impact simulation

Parameters Measured:

Surface deformation and damage assessment

Structural integrity verification

Mounting system stability

Component displacement analysis

2. Material Strength Evaluation

Testing Focus:

Front surface hardness and flexibility

Frame and support structure durability

Fastener and connection point integrity

Protective layer effectiveness

3. Progressive Damage Analysis

Assessment Criteria:

Initial impact resistance capability

Progressive failure patterns

Multiple impact performance

Failure point identification

Key Testing Standards and Certifications

International Standards Compliance

IEC 60068-2-75: Environmental testing - impact test methods

ISO 9001: Quality management systems

EN 12600: Glass in building - pendulum impact testing

ASTM D2794: Organic coatings - impact resistance

Sports-Specific Certifications

FIFA Quality Programme: For international football venues

IAAF Certification: Athletic stadium requirements

NBA/NFL Approval: League-specific safety standards

IPC Class 2 Standards: Electronic assembly reliability

ABXLED Impact Testing Methodology

Laboratory Simulation Testing

Facility Capabilities:

Custom impact testing apparatus

High-speed camera analysis (10,000+ fps)

Force measurement up to 5000N

Environmental conditioning chambers

Field Testing Procedures

Real-World Validation:

Controlled live environment testing

Long-term durability monitoring

Extreme condition performance verification

Maintenance impact assessment

Test Parameters and Metrics

Impact Energy Levels:

Low energy (5-15J): Minor contact simulation

Medium energy (15-50J): Player collision simulation

High energy (50-100J): Equipment impact simulation

Extreme energy (100J+): Safety factor verification

Design Features for Enhanced Impact Resistance

Protective Front Surface Design

3-8mm Tempered Glass: High-impact transparent protection

Polycarbonate Layers: Shatter-resistant alternative options

Anti-Glare Treatments: Maintained visibility with added protection

Easy Replacement Systems: Quick damaged panel replacement

Reinforced Structural Elements

Aluminum Alloy Frames: High strength-to-weight ratio

Shock-Absorbing Mounts: Vibration and impact dampening

Redundant Support Systems: Backup safety mechanisms

Modular Design: Localized damage containment

Advanced Protective Technologies

GOB (Glue-on-Board) Protection: Enhanced LED module durability

Conformal Coating: Moisture and impact protection

Shock-Resistant Components: Vibration-proof internal mounting

Cable Management Systems: Secure internal connections

Case Study: ABXLED Stadium Perimeter Display Testing

Project Background

Venue: 50,000-seat international football stadium

Display Type: Perimeter LED advertising system

Testing Duration: 6-month comprehensive program

Compliance Goals: FIFA Quality Programme certification

Testing Protocol Implementation

*Phase 1 - Laboratory Testing*

100+ controlled impact tests at various energy levels

Temperature cycling from -20°C to 50°C

Humidity exposure from 20% to 95% RH

UV radiation accelerated aging

*Phase 2 - Field Validation*

3-month live environment monitoring

Simulated player collision scenarios

Maintenance access impact assessment

Emergency situation response testing

Results and Certification

Impact Resistance: Withstood 75J impacts without structural failure

Safety Compliance: Exceeded FIFA requirements by 40%

Operational Reliability: Zero failures during testing period

Certification Achieved: FIFA Quality Programme approval

Maintenance and Inspection Protocols

Regular Safety Inspections

Weekly Checks:

Surface condition assessment

Mounting hardware verification

Structural alignment confirmation

Protective layer integrity

Quarterly Comprehensive Reviews

Detailed Evaluation:

Impact history documentation

Component wear analysis

Safety system verification

Performance benchmarking

Documentation and Compliance

Impact Event Logging: All incidents recorded and analyzed

Preventive Maintenance Scheduling: Proactive component replacement

Safety Certification Renewal: Annual compliance verification

Training Documentation: Staff competency records

Industry Best Practices

Design Phase Considerations

Early safety integration in product development

Athlete perspective in risk assessment

Multi-disciplinary design team collaboration

Prototype testing and iteration

Installation Quality Assurance

Certified installation teams

Torque-controlled fastening systems

Alignment verification protocols

Load testing verification

Ongoing Safety Management

Regular staff safety training

Emergency response procedures

Incident reporting systems

Continuous improvement processes

Future Trends in Impact Resistance Technology

Advanced Materials Development

Self-Healing Polymers: Automatic minor damage repair

Composite Materials: Enhanced strength with reduced weight

Smart Sensors: Impact detection and location systems

Adaptive Structures: Dynamic response to impact forces

Testing Methodology Evolution

Virtual Simulation: Computer-based impact modeling

AI-Powered Analysis: Predictive failure point identification

Real-Time Monitoring: Continuous structural health assessment

Advanced Materials Testing: Nanotechnology integration

Why Choose ABXLED for Stadium LED Displays?

Proven Safety Record

50+ international stadium installations

Zero safety-related incidents

Comprehensive testing documentation

Industry-leading safety margins

Technical Expertise

Dedicated sports venue engineering team

Custom testing facility capabilities

International standard compliance

Continuous safety innovation

Quality Assurance

Multi-stage impact testing protocol

Independent third-party verification

Comprehensive documentation

Ongoing performance monitoring

Conclusion

Impact resistance testing is not merely a compliance requirement but a fundamental responsibility in stadium LED display manufacturing. Through rigorous testing, innovative design, and continuous improvement, ABXLED ensures that our displays provide unmatched safety and reliability in the world's most demanding sports environments.

Contact ABXLED today to learn more about our impact-resistant stadium LED displays and comprehensive testing protocols.

Trailer LED display

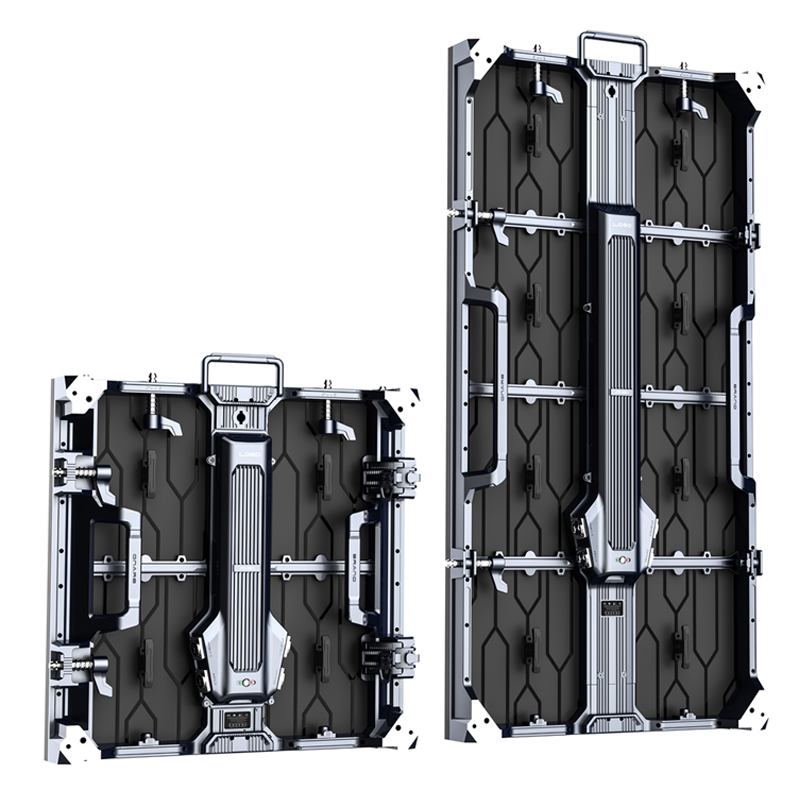

Trailer LED display  ABXLED RT Series Transparent r...

ABXLED RT Series Transparent r...  ABXLED RR 1000series rental LE...

ABXLED RR 1000series rental LE...  ABXLED ROMA series stage renta...

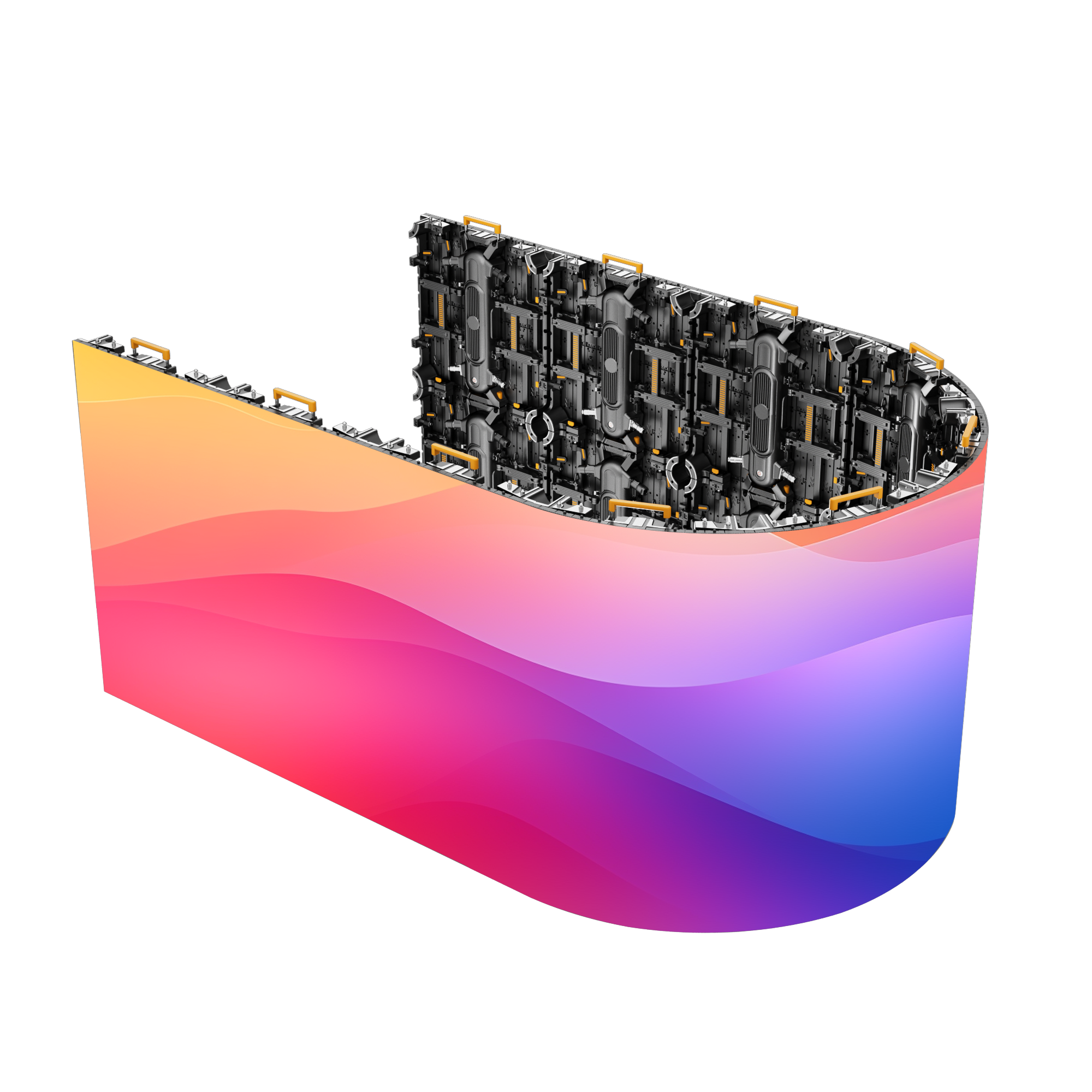

ABXLED ROMA series stage renta...  ABXLED RF Series Flexible ren...

ABXLED RF Series Flexible ren...  ABXLED RD 500 series stage ren...

ABXLED RD 500 series stage ren...  ABXLED SD 960 Series Stadium L...

ABXLED SD 960 Series Stadium L...  ABXLED SA 960 Series Stadium L...

ABXLED SA 960 Series Stadium L...  Poster LED Screen – FS Standin...

Poster LED Screen – FS Standin...  Indoor Tri-fold LED Poster Dis...

Indoor Tri-fold LED Poster Dis...  Poster LED Screen – FO Standin...

Poster LED Screen – FO Standin...  Outdoor LED Poster screen

Outdoor LED Poster screen  Naked-eye 3D Outdoor LED Scree...

Naked-eye 3D Outdoor LED Scree...  ABXLED Oi series 960x960 Outdo...

ABXLED Oi series 960x960 Outdo...  ABXLED OD series 960x960 Outdo...

ABXLED OD series 960x960 Outdo...  ABXLED OA series 960x960 Outdo...

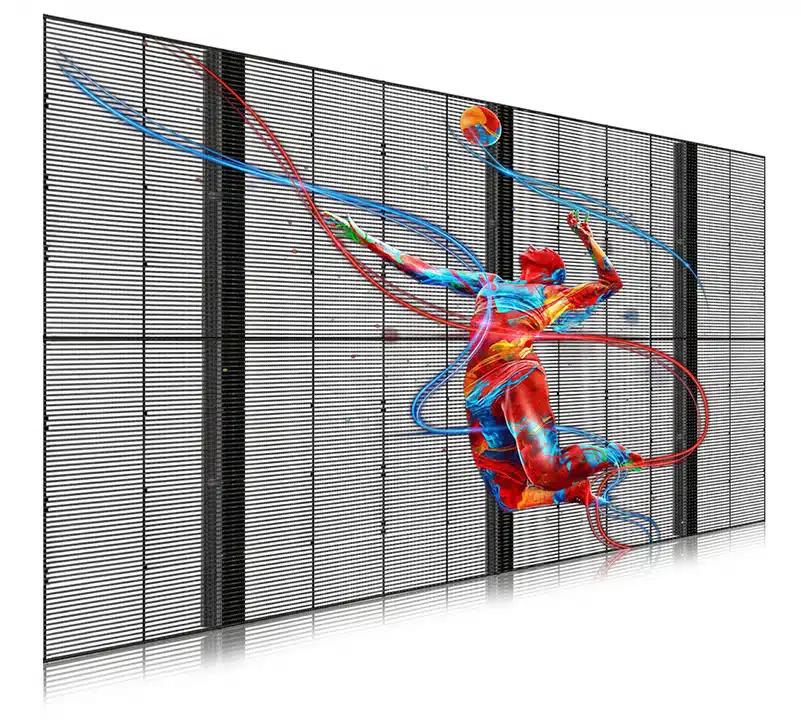

ABXLED OA series 960x960 Outdo...  Transparent LED Display

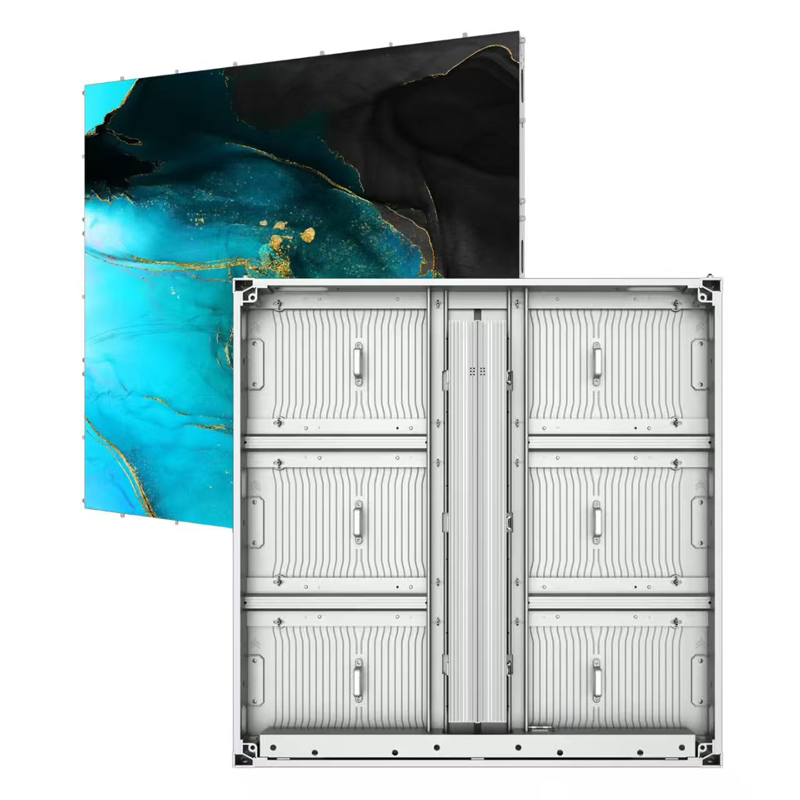

Transparent LED Display  HD 1000 Series LED screen

HD 1000 Series LED screen  HD 640 Series LED display

HD 640 Series LED display  HD 600 Series COB LED screen

HD 600 Series COB LED screen  LED Sphere Display

LED Sphere Display  LED Can display

LED Can display  DJ Booth LED Screen

DJ Booth LED Screen